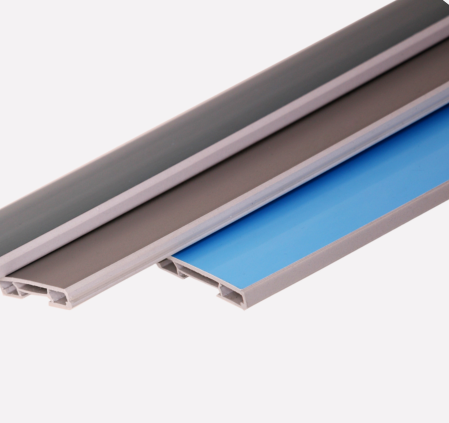

PP furniture edging

Polypropylene furniture edges are a modern and environmentally friendly solution for the protection and design finishing of furniture boards. Due to their durability and sustainability, they are becoming an increasingly popular alternative to ABS edges.

SURFACE TREATMENT

PP furniture edges are produced by extrusion of polypropylene in a wide strip of various thicknesses with the following surface treatment:

| double-sided corona activation of the surface

| application of (adhesive coating) primer from the bottom side

| application and curing of UV varnish from the visible side

The PP furniture edge is then cut from the so-called “jumbo roll” to the required width.

The edge is temperature-stable, durable and resistant to scratches under mechanical stress.

PRODUCTION RANGE

| Width [mm] | Thickness [mm] | |

| Edge band (cut furniture edge) | 15-60 | 0,5-2 |

| Jumbo roll (uncut strip) | 410 | 0,5-2 |

CUSTOM PRODUCTION

Possibility of manufacturing PP furniture edges according to customer requirements.